The world of rigging? Let's find out more.

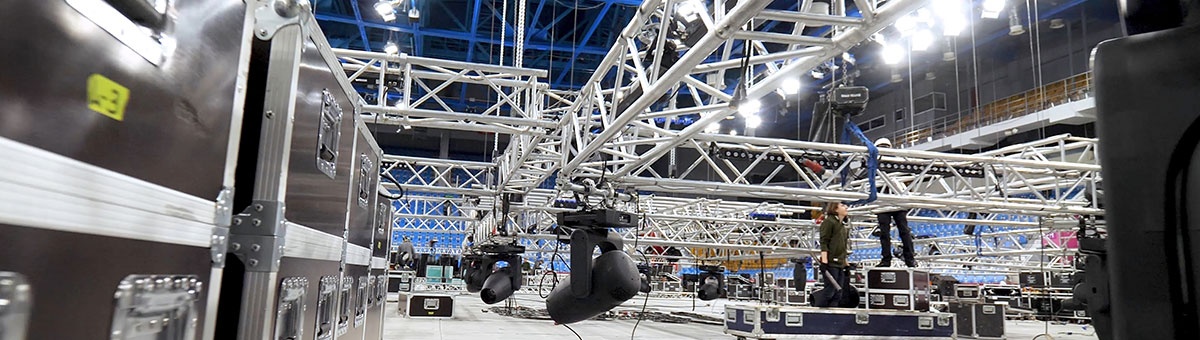

The world of live shows, especially concerts, regardless of the size and complexity of the event, always requires a series of infrastructures (stages, platforms, trusses...) to ensure the success of the event and the safety of all participants. Rigging, the installation of suspended structures to support lights, screens and sound equipment, plays a crucial role and, as we like to say, 'it must be chosen and handled with care'. From platforms and lifts (ground support) to suspended structures (fly rigging), installation must be carried out with precision and expertise to support the weight of artists, technicians and show equipment. Safety is therefore paramount: errors in design or assembly can have very serious consequences, so strict protocols and highly skilled personnel are essential.

This is a necessary premise, a set of golden rules that even we here at Frenexport have firmly implanted in our minds before we set off on our latest adventure in the world of rigging.Let's take a small step back to better define the subject, commonly known as the "world of rigging" or "trussing", to better explain what it is and what materials and tools are used. It would be fair to say that there are at least two different types of applications and tools, two ‘families’: everything that can be classified as ground support and flying rigging.

Fly Rigging or Overhead Rigging

This is the most common form of rigging where equipment is suspended above the stage or audience area. It is used for large events and shows where lighting, sound or video equipment needs to be suspended from overhead suspension points, such as fixed roof structures or temporary truss.

Ground Rigging

This method of rigging involves supporting trusses and equipment from ground structures without using overhead suspension points. It is used when there are no sufficiently safe structures for aerial rigging or when working in confined spaces.

Both types of rigging are commonly used in events and are chosen according to the needs and applications. A typical and well known case of flying rigging is the installation of line array sound systems, generally used in large events, while a typical ground support application is represented by stands placed on the ground to lift loudspeakers or bars for lighting.

Frenexport's commitment to the world of rigging, which we now know and understand better, stems from our desire to offer our customers a 360° range of products and technologies, as our company has been active for years in the world of pro audio, pro lighting, video and now structures.

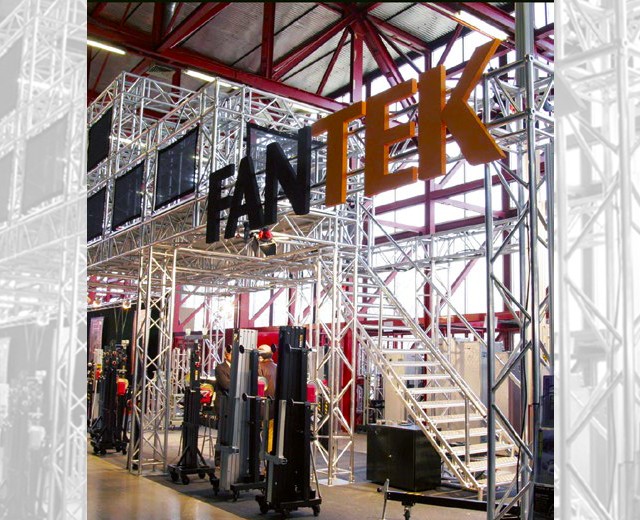

FANTEK

The distribution of Fantek, a world leader in the sector, which Frenexport exclusively distributes for the country, was a recent important step. The company's history began in 1940 with the manufacture and marketing of metal structures and lifting towers, before stage platforms were added in 2008. Since then, the company's offer has been consolidated into three main product ranges: lifting towers, trusses and stage platforms. To mention just a few of the products that have become very popular over the years, the Lifter range of the FT series (FT 6033, FT 5323, FT 7045) or the smaller and lighter, but nevertheless powerful and robust top loading of the T series (T101D, T103D ). Of course, the entire range of trusses is also available in different shapes and sizes to meet the needs of small, medium and even large users.

CENTOLIGHT

Centolight is not just 'light'! Recently, this Frenexport-owned brand has also been dedicated to the production and marketing of stages, platforms and accessories for the stage, ready to use and available in our warehouses.

In this case too, the first rule is safety! For this reason, the materials and partners have been selected within the European Community, where regulations in this sector are very clear and rightly restrictive. This is how the CL line was born, which includes various models of stage platforms, such as the CL-SDP-2X1 (200 x 100 cm) or the CL-SDP-1X1 (100 x 100 cm), as well as many other products of different sizes and shapes, connection clamps, levelling clamps, stage skirts and access ladders, such as the CL-ADST4S-60 model, a 4-step ladder adjustable from 60 to 100 cm. The catalogue is constantly being developed and at the time of writing there are interesting new products on the way.

If you would like to know more about the world of trussing (and we still call it that for convenience...)

and find out which products might be right for you